About Megnajet

Fluid systems solutions from application concept through to customer commercialisation

-

We have over ten years of experience with fluid management systems operating in a broad range of applications

-

Our fluid management systems are easily integrated into a variety of set ups and are all built using industrial components to withstand harsh and dirty environments

-

With a start-up and settle time on the unit typically less than two seconds, our systems are always ready to start printing

-

Our state-of-the-art systems are well equipped with innovative features and functionality, enabling advanced levels of control designed to meet customer needs

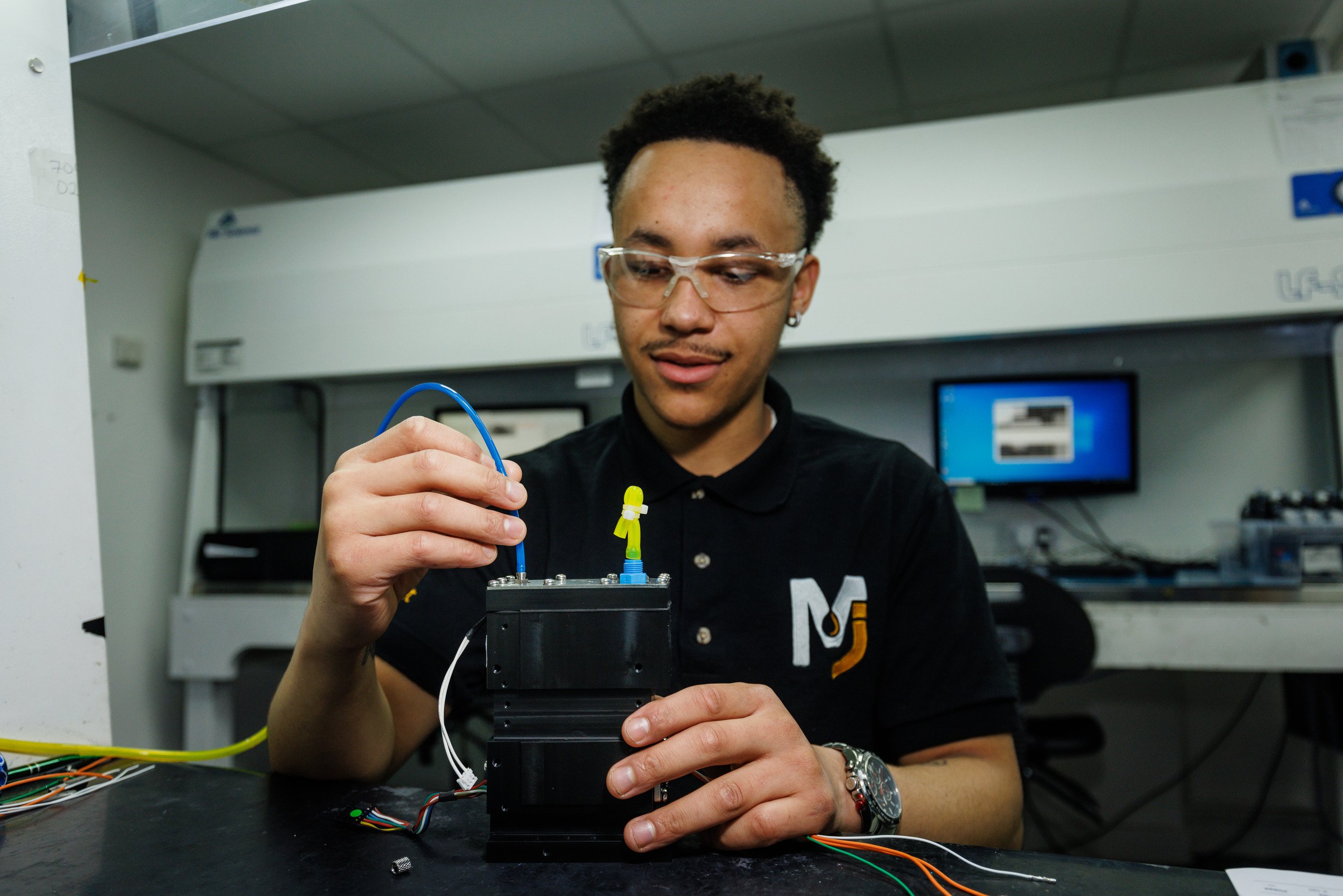

Megnajet is a fluid management system specialist with over ten years experience, propelling customers to a successful inkjet development project.

We design and build breakthrough products - from application concept through to customer commercialisation bringing inkjet to life. Our expertise covers a wide range of applications with industry proven technology and a range of products to cover all stages of the customer product development cycle.

Fuelled by our passion to meet customer needs and commitment to providing a reliable and robust solution, our goal is to help customers get to market quickly with reduced development costs and for them to be successful.

Management Team

-

Mike Seal

General Manager

-

Adam Eaton

Engineering Manager

-

Andy Jinks

Operations Manager