Fluid management system specialists

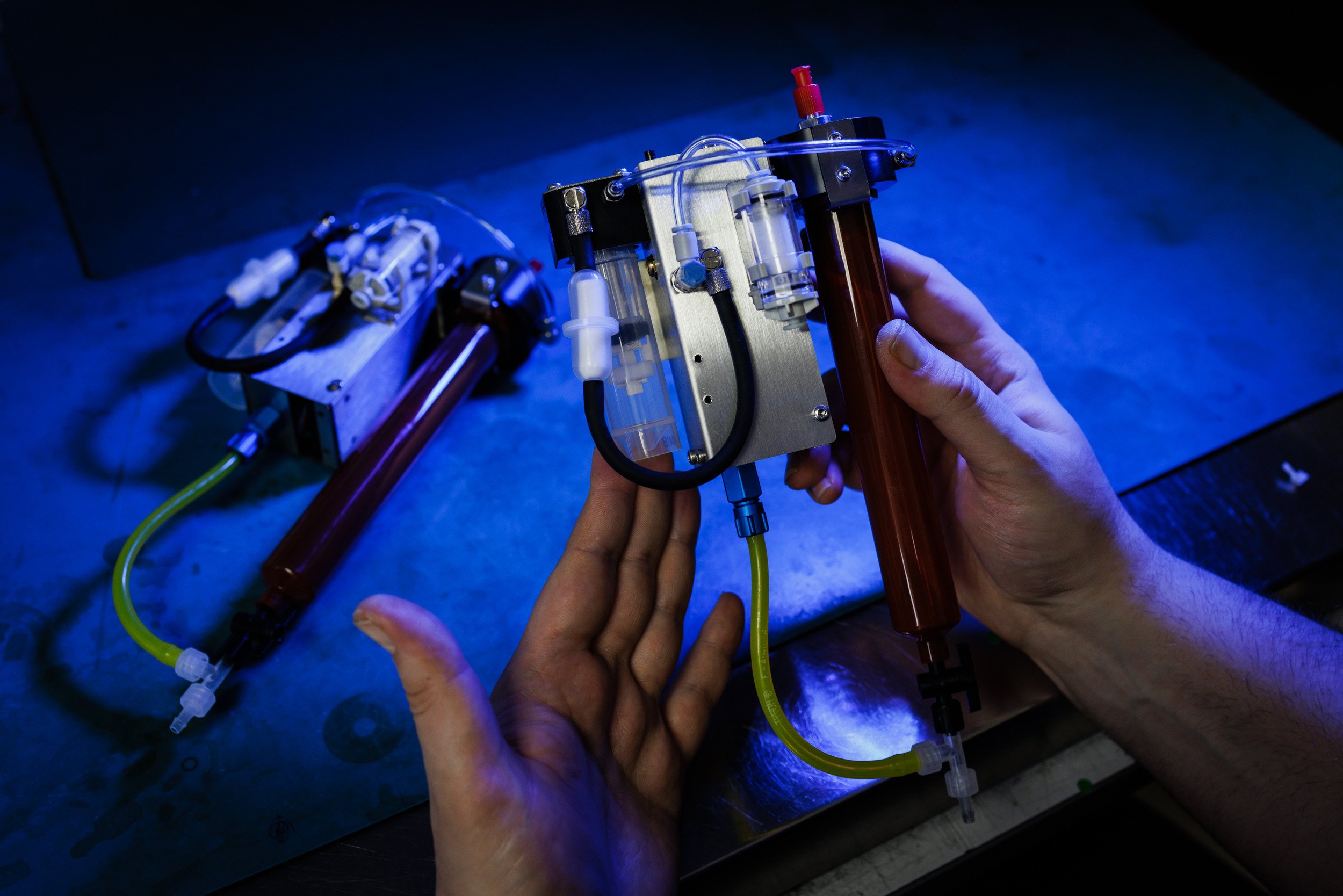

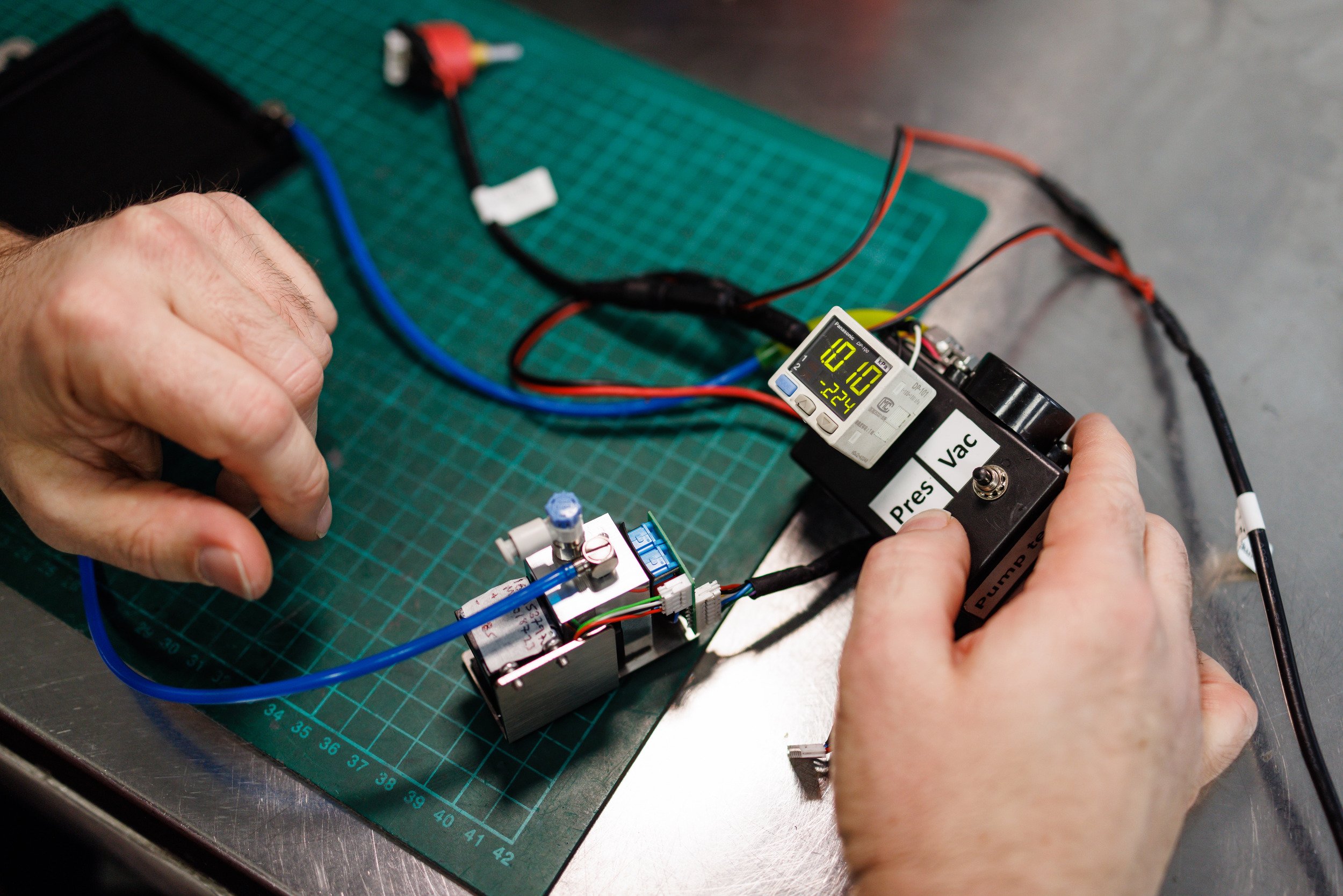

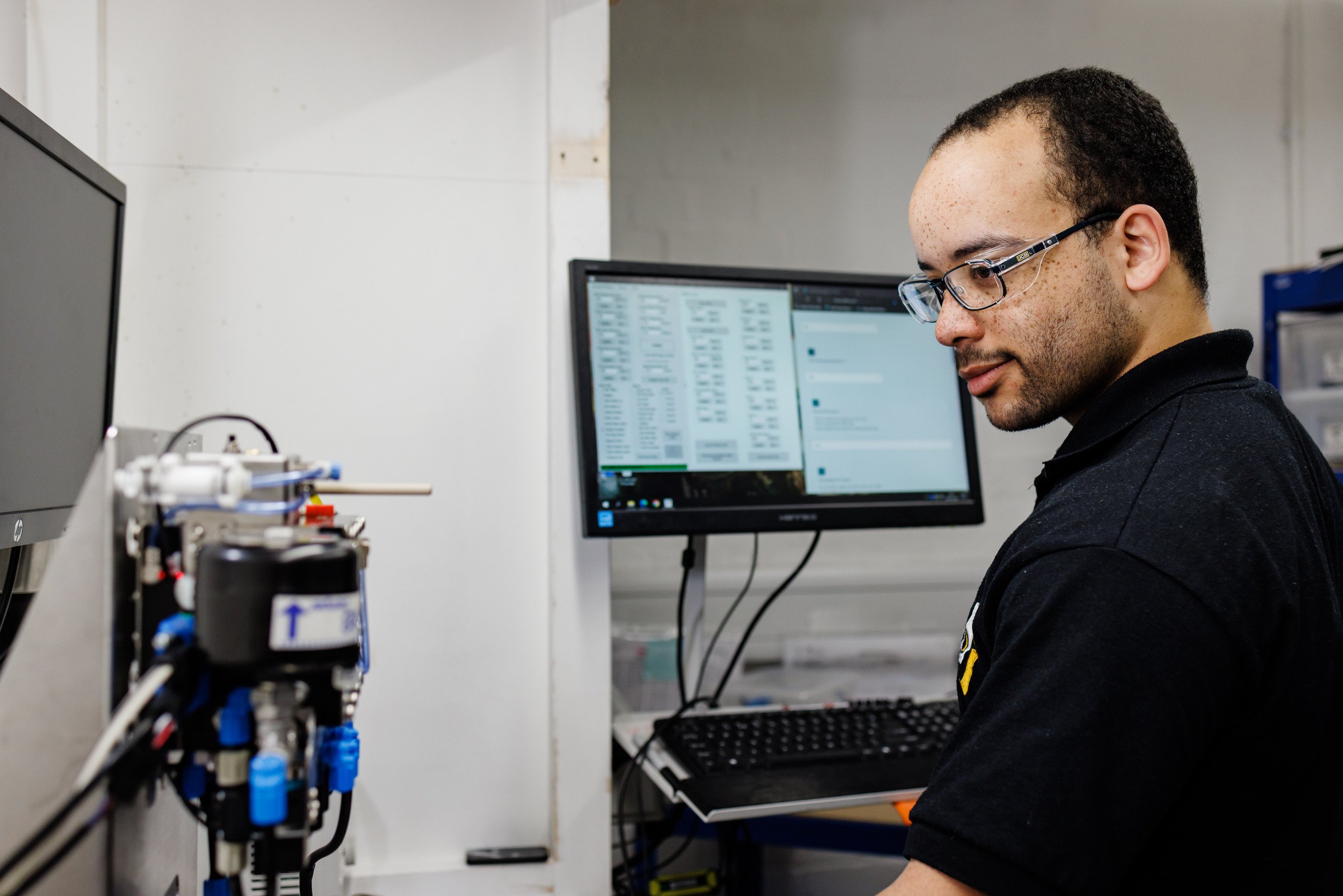

With over ten years’ experience in inkjet fluid systems and a broad product portfolio covering a wide range of industries, applications and printhead types, Megnajet offers fluid systems solutions from application concept through to customer commercialisation making us the unrivalled inkjet fluid system specialists.

Easily integrated industrial inkjet products

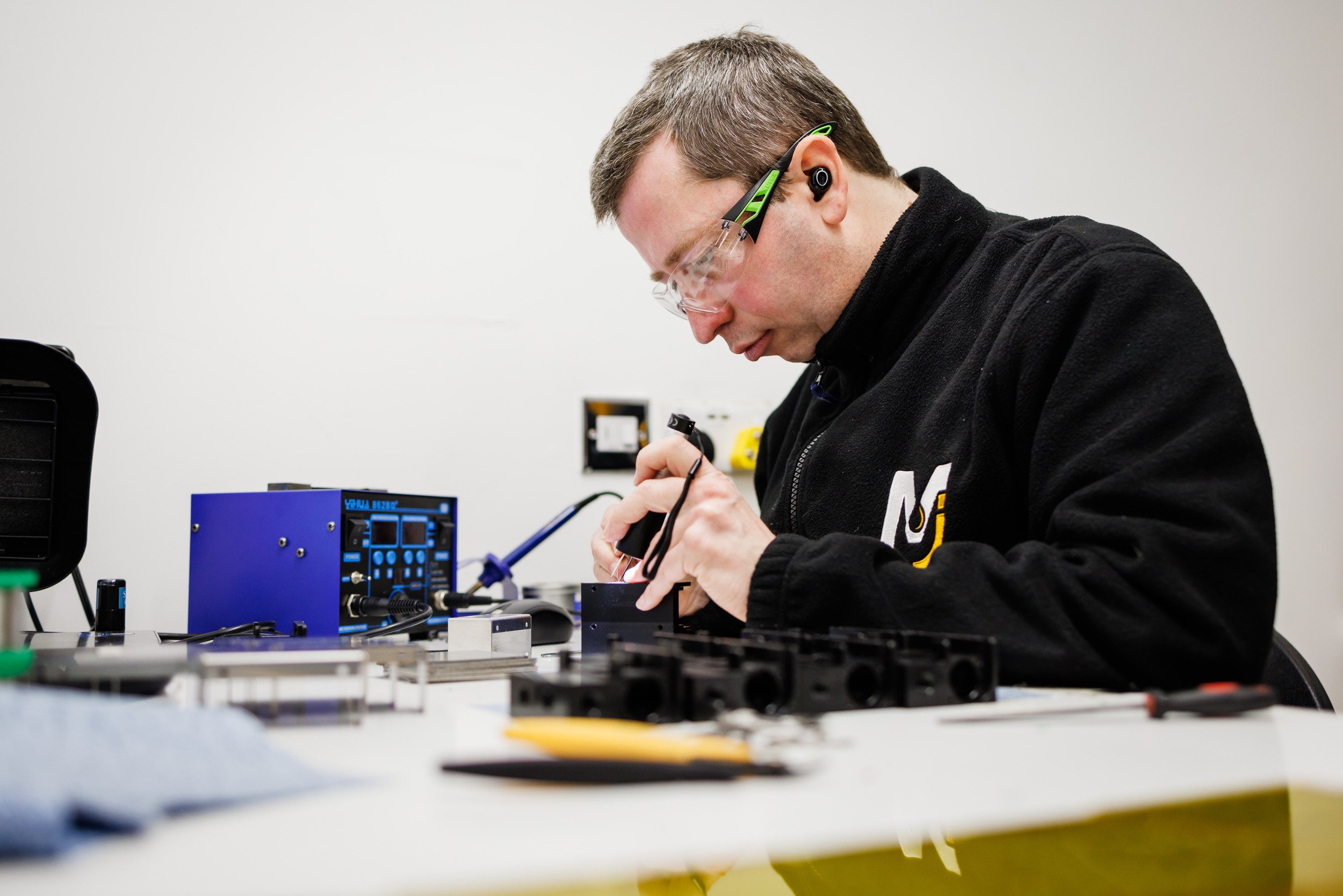

We offer both OEM component and fully out of box fluid system solutions which are feature rich, easy to integrate, durable and robust, saving you time and development costs.

Latest news

“Our products are designed with extensive customer feedback in order to meet the industry’s most demanding needs. With our dynamic approach to innovation, we use proven technology to deliver exceptional products, enabling our customers to get to market more quickly.”

— Mike Seal, General Manager